Safety, Harassment Prevention

and Other Training Courses

ROSTERS & LISTS

West Coast industry rosters and training lists contain more than 55,000 highly trained and qualified employees spanning more than 125 job classifications. We help ensure workers meet the criteria for employment in the industry.

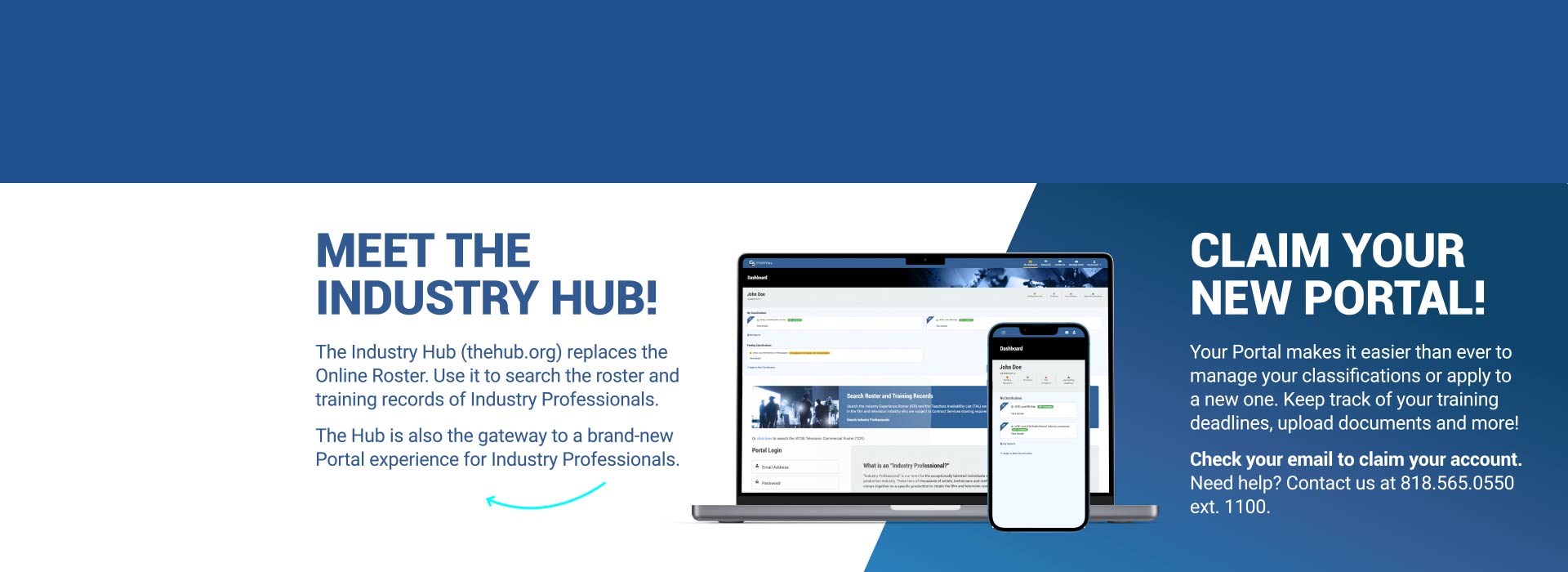

Search the Industry Hub (NEW!) Learn More About the Hub (NEW!) Industry Experience Roster Teachers Availability List / Dual Credential Substitute List Local #800 Experience Registry Website Television Commercial Roster SAG-AFTRA Training List

TRAINING

We offer online and in-person training as well as "blended" courses, which contain a blend of both online and in-person instruction. We offer 37 courses, including 32 safety courses, 2 harassment prevention courses, 1 required skills course, 1 COVID-19 prevention course, 1 identifying and reporting child abuse and neglect course, and additional training found below.

Safety Training Harassment Prevention Training COVID-19 Prevention Training Apprenticeship Programs Upgrade Training

OTHER SERVICES

Whether it’s drug/alcohol testing, licensing/certification reimbursements, or other vital tasks, we are the administrative backbone of the industry, handling these functions and relieving each signatory employer from having to perform these services themselves.

CS Access Mobile App Local #399 Transportation Services Nationwide Transportation Services Update My Personal Info Reimbursements Form I-9 Services Teacher Services

PRODUCTION AFFAIRS & SAFETY

We offer the latest resources, news and best practices on workplace safety. We consider it a very serious responsibility to make sure we have not only the most talented, but also as safe a production workforce as anywhere in the world.

Safety Hotlines Safety Bulletins COVID-19 Return-to-Work Info Production Notices Studio Zone MapFor more than 50 years,

Contract Services has served the motion picture and television industry, preparing a workforce of over 55,000 individuals and ensuring that vital behind-the-scenes functions are carried out safely, smoothly and efficiently.

From acclaimed industry-wide safety training to full administration of industry rosters, Contract Services helps industry professionals remain current in their craft – and competitive in the marketplace. With a new state-of-the-art training facility, we offer a “one-stop shop” for meeting a wide array of contractual, legal and regulatory requirements.

In an industry that’s growing and evolving, we’re keeping pace every step of the way.